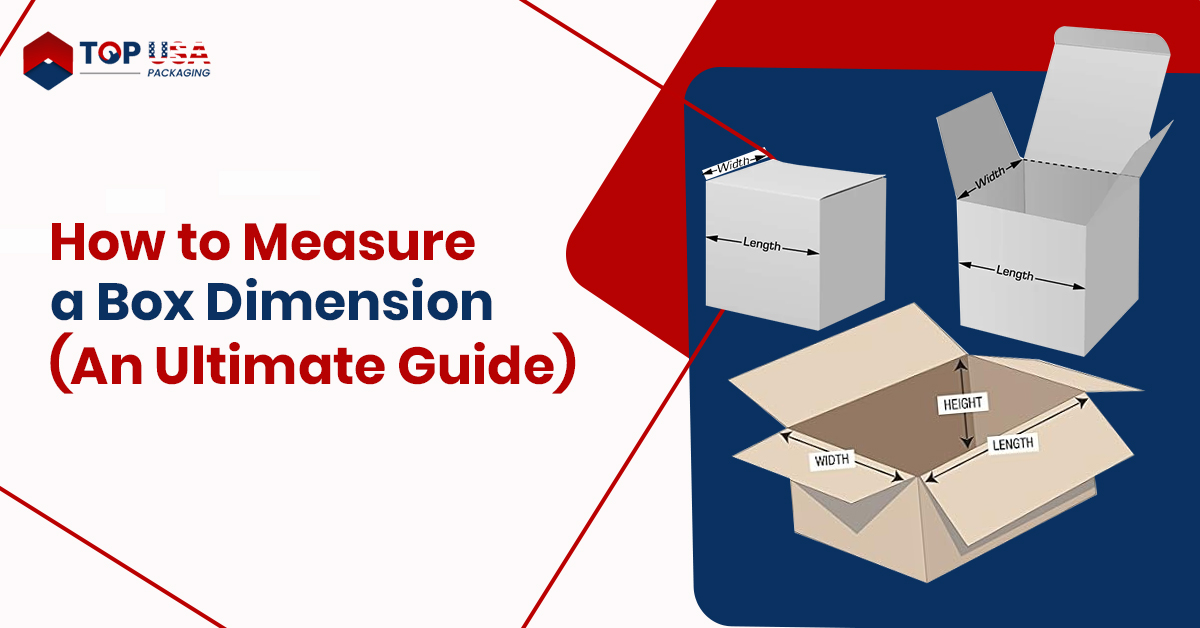

How to Measure a Box Dimension – An Ultimate Guide

The answer to this question “how to measure a box dimension” is pretty straightforward and a must to have knowledge about. The only trick to measure and create a box perfectly is putting attention to detail. Correct measurement ensures maximum product safety because there shouldn’t be space for the item to roam around in the package. The lesser the space for the product to move around in the box will automatically reduce the chances of damage during transit. Nobody likes ill-fitting boxes due to their clumsy appeal. Moreover, with oversized box dimensions, the material usage, storage capacity, production cost and warehousing costs will be significantly impacted. It is a waste of money and resources that could come in handy for other needs.

With that being put out there, more tight-fitted boxes are also a no-go. Small gable boxes will have close to no space to fit the product without having any shape deformity. If inserts are a must the box will tear apart because of extra filling. Consumers might have a tough time gaining access to their long-awaited product.

The last thing businesses want in this fierce competition is to give their beloved consumers a dull unboxing experience. There’s a lot at stake and an ill-fitting box can easily tarnish your brand and product image that’s why we have written this blog about how to measure a box dimension. To assist you in crafting the best-looking and appropriately fitting boxes for your prestigious products.

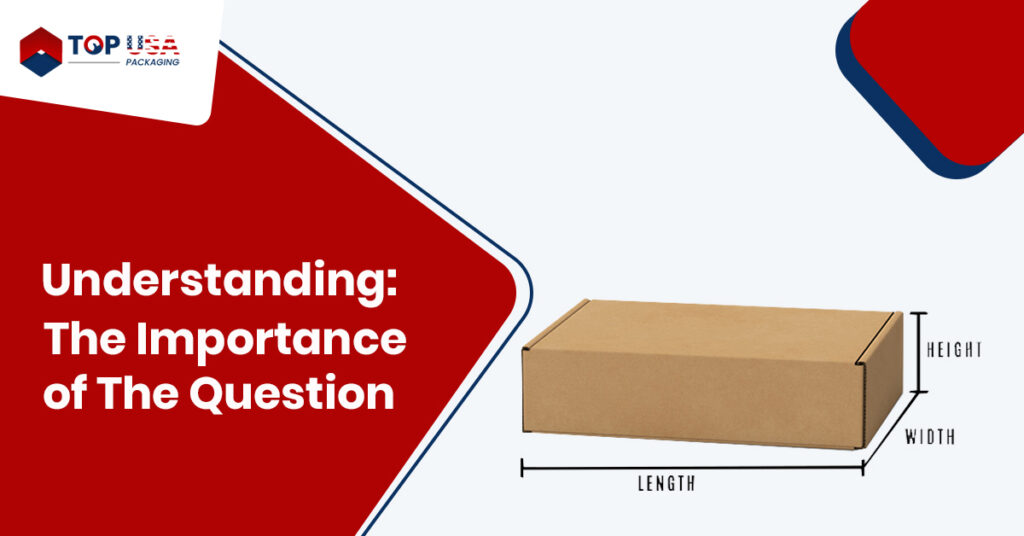

Understanding: The Importance of The Question

How to Measure a Box?

Knowing box measurements is crucial for businesses, so they can pack their merchandise in a perfectly sized box. If you are shipping your products in a box even minute measurement alterations can impact the weight, space and shipment fares making you lose money over centimeters of cardboard. There’s also a big chance that your box might rip off if the product doesn’t fit well in it, which makes accurately and precisely measuring the box quite crucial.

Read More: What Does Collate Mean When Printing

How to Write Measurements?

The more clarity the better in writing measurements, here are some tips you can follow when writing box measurements:

- Use numerals i.e. 4, 5 rather than alphabetical terms like four, five for a more cohesive and simple understanding.

- Always justify the unit of measurements like inches and centimeters.

- Add space between the numeral and the unit.

- You can also use units in abbreviated forms like cm and kg.

- Box Dimensions like length width height must be expressed.

- The multiplication symbol must be written in between to distinguish the formula.

- There should not be any use of decimals for more consistency

How are measurements listed?

The queries how are measurements listed? and how are dimensions listed? Are answered exactly the same way, the orders are listed below:

For cuboidal and cubic boxes:

The box dimensions order that is standardized is usually described as Height x Width x Length (LxWxH).

For example: 13 inches L x 10 inches W x 6 inches H

For cylindrical boxes:

Cylindrical tube, tin, can or box measurements are described as Height x Diameter (HxD).

For example: 5 cm D x 11 cm H

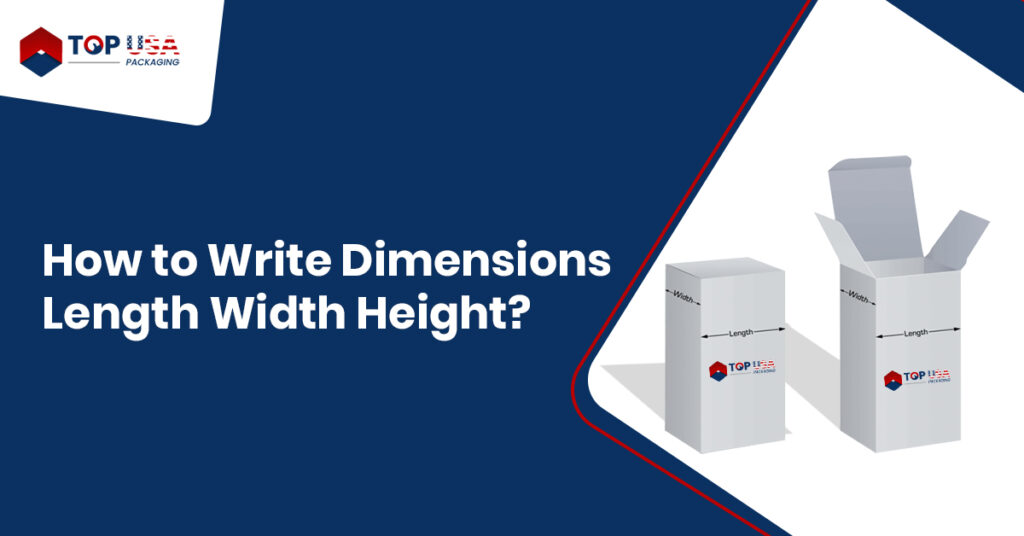

How to Write Dimensions Length Width Height?

To actually know the dimension order, one must need to have a detailed understanding of these terms and it is necessary to fully answer how to measure a box for you. There are three main dimensions order by which a box a measured: Length Width Height. Firstly, the box top opening is measured by applying the formula: L x W x H.

Read More: How Much is a Quarter

What is Length and Width?

Length (L) is the side of the box that is the longest with a side flap when observed from the top. Whereas, width (W) is the side with a flap of the box that is shorter than the length, also when observed from the top and the perpendicular to both length and width is the height (H). Height or depth is the shortest dimension among all dimensions.

Difference Between Length and Width?

Both are important as box dimensions order but there is an evident difference that length is longer and width is shorter but if the box is facing in an upward direction, then the longest dimension would be height even leaving length as a shorter dimension. A cubic box is actually equal from all sides, which makes the task rather easy but the packaging must be according to the form and size of the product to properly hold it. With that being said, still any type of box will be measured in the standard box dimensions order before going into production.

What order do dimensions go in?

It is a major question of brands wanting a perfect box, they always ask about what order are dimension listed, it is not very complicated, the order of dimensions is typically described as the volume whose formula is “Length x Width x Height” or written in acronyms “L x W x H”.

Dimensions Order of Shaped Boxes

Boxes are created in many different shapes and “how to measure a box” applies differently to the type of shape you went for. Let’s dive into the box dimensions order or measuring techniques for the most go-to shaped boxes. You can also check our unique shaped pizza boxes.

· How to Measure a Box of Square Shape?

Cubic or square boxes are the most opted box type, they are suitable for packaging small and medium-sized products. It is the simplest shape for box measurements as compared to other shapes. The equivalent structure provides sturdiness and shipping stability, CBD brands mostly go for square-shaped boxes to showcase their products.

The dimension order goes like multiplying length, width and height to get their required volume as a cubic=shaped box. Measuring square box dimensions is the easiest thing, one side of the box is equal to all sides so just getting one measurement will give you the value of all dimensions like Length = Width = Height.

· How to Measure a Box of Triangular Shape?

It is tough to measure the dimension order of triangular-shaped boxes. Let us tell you the way of measuring triangular box dimensions.

Firstly, the triangular box dimensions are measured like height must be calculated then the base, which is length x width or B = L x W. To measure the triangular box volume the formula is used like V = ½ x B x H, to get the exact area of the triangular box.

· How to Measure a Box of Cuboidal Shape?

Cuboidal boxes are among the most widely used for packaging and shipping, with varying shapes some having longer lengths, widths, or heights. These boxes often have irregular shapes, and understanding their exact dimensions order requires knowing the proper method of measurement. Food, perfume, liquor and retail packaging boxes are usually rectangular and are sold in large quantities daily, making accurate measurement essential.

To measure a rectangular box, you need to assess each side individually: length, width, and height. The length refers to the longest side, the height is typically in the middle, and the width is the shortest, though this isn’t always the case. Measure from top to bottom for height, the longest side for length, and the shorter side for width. To calculate the box’s volume, multiply length by width by height (L x W x H), remembering to factor in material thickness.

Read More: Types of Tape

How to Measure a Box: Main Considerations

When selecting the appropriate box dimensions, shape or size, it’s important to consider three key factors: external dimensions, internal dimensions, and score-to-score dimensions.

External Dimensions

Once a corrugated packaging boxes is assembled, its external dimension order represents its overall size, which is important for shipping and inventory purposes. For instance, the 10″ x 10″ x 6″ box mentioned earlier might measure 10 3/8″ x 10 3/8″ x 6 5/8″ when fully constructed.

External dimensions provide the resultant packaging boxes dimensions but it doesn’t account for the thickness of the material. As a result, they are not the most accurate measurements to share with your packaging partner for precise manufacturing.

Internal Dimensions

When any box is crafted and then assembled, its interior dimensions represent the available utilizable space for the product. These interior box measurements are the industry standard for determining how well a product will fit inside the box.

When boxes are ordered, the order of dimensions provided by the customers typically refers to the interior space. To exemplify it for you, if a box order of dimension is 10″ L x 10″ W x 6″ D it will have 10 inches of free space from length to width or side to side and 6 inches from the bottom to the top (height).

Interior dimensions are essential when selecting or designing a custom box to fit your product. However, if you’re trying to replicate an existing box, these measurements may not be the most precise to convey to your manufacturer.

Score to Score Dimensions

The most efficient approach is to thoroughly recreate your box measurements with a packaging manufacturer is by employing score-to-score dimensions for measurement and calculation. These dimensions represent the distance between the box’s fold lines (scores) and account for the thickness of the corrugated board, also referred to as material allowances.

Score-to-score measurements typically fall between the interior and exterior dimensions of the box, offering a more precise sizing method.

Also Read: Collated vs Uncollated

Issues Regarding These Box Dimensions

Although determining the dimensions of your package by measuring its length, width, and depth and calculating its volume may seem straightforward, there is one crucial factor to consider: the difference between internal and external measurements.

The box dimensions or box measurements industry standards rely on internal measurements, not external ones, which are critical to ensuring the packaging fits your product perfectly for an increased appeal. Internal dimensions are much more accurate for both manufacturers and your products. While it might feel easier to measure a box’s external dimensions, interior measurements are what truly matter for custom packaging projects.

Manufacturers often distinguish clearly between internal and external sizes. Measuring internal dimensions guarantees that your product fits securely inside the box, leaving minimal space for movement. This helps protect your products during shipping and ensures consistent quality. Conversely, using external measurements can be misleading, as they don’t account for the thickness of the box, which could result in packaging that doesn’t fit your product properly, especially with corrugated boxes, where the fluted structure adds thickness.

For more precise results, always measure the internal dimensions of your box.

How to Measure a Box Size in Volume?

There are two main methods for measuring the size of a box. The first is using a ruler or measuring tape to determine the box’s length, width, and height. The second methods involve referencing the box dimensions that are listed, which include its length, width, and height.

Understanding the box’s volume is crucial for optimizing shipping, warehousing, and distribution. It also helps determine how well your product will fit inside the packaging. Calculating volume is essential for material and cost efficiency, as well as for proper structural design, so don’t overlook this step!

Once you know the basic dimensions, calculating the volume becomes straightforward. Simply multiply the three dimensions:

Formula: Volume (Vol) = Length x Width x Height or Depth.

Common Errors When Selecting the Correct Box Size

Selecting the wrong box size can cause multiple issues during packing and shipping. To avoid these problems, here are some common mistakes to watch out for:

Overlooking Item Measurements

One major error is not measuring your items before choosing a box. Always ensure you take precise measurements of the item’s length, width, and height to guarantee a snug fit.

Assuming All Boxes Are Alike

Not every box is designed the same way. Never forget to check the weight capacity, durability and strength of the box. Using a weak box for heavier items can lead to it collapsing and damaging your goods.

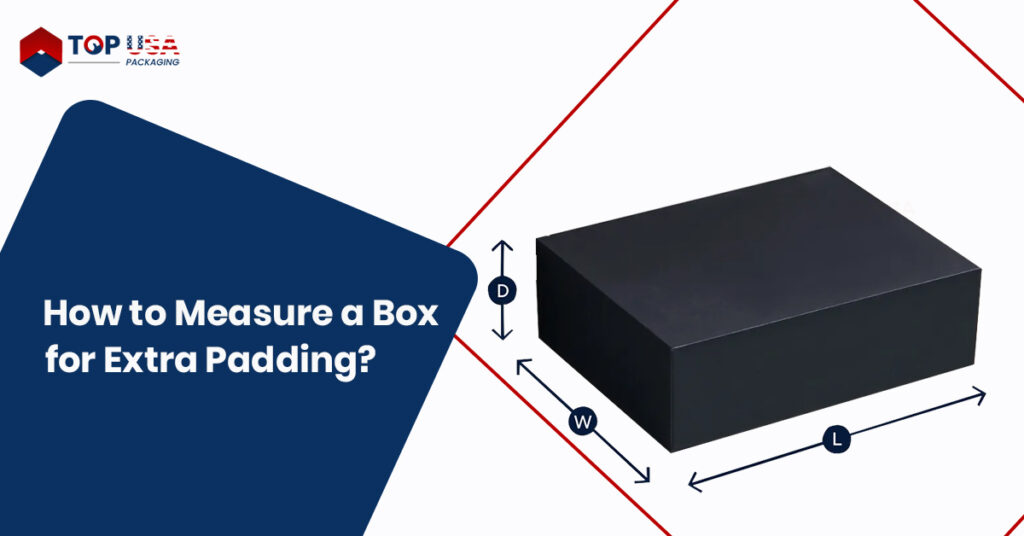

How to Measure a Box for Extra Padding?

When products face long transits or the possibility of rough handling, adding extra padding to boxes for enhanced protection is crucial, especially for delicate items. However, incorporating additional padding requires extra space within the packaging.

This just conveys the message that your box dimensions order will need to be increased accordingly with the inserts and product. The size you order should be based on the type of padding you’re using. In the case of bubble wrap used to insulate and protect delicate products, it may require the addition of around 4 to 5mm to each of the three dimensions (length width height). In summary:

Cushioning Options for Packaging

Be sure to leave enough space for cushioning when determining the final dimensions of your box. Try to be precise while allowing room for padding. Consider these common cushioning materials:

- Air cushions

- Bubble wrap

- Styrofoam

- Tissue paper

- Crumpled newspaper

- Expandable foam

Cushioning and Packaging

Some materials require more space than others, so choosing the right cushioning can significantly impact box dimensions and cost. Maintaining harmony between protection and value is integral. It’s a good idea to test the cushioning with a single box first. By dropping the padded package a couple of times, you can assess its ability to withstand rough handling.

Additionally, be mindful of specific padding guidelines from courier services, as many recommend at least two inches of protective padding for fragile items.

Final Words!

Box dimensions are an important aspect to consider if you want to have an unforgettable impact with boxes complimenting your products precisely. We hope that now you know how to measure a box and tell us all your requirements, we can assist you in finding the best box size for your merchandise. With our accurate measurement techniques, your products will reach their destinations unharmed and guess what we don’t charge for shipping. Contact us because we are eagerly waiting to assist you in this packaging journey with the help of our phenomenal graphic designers and to make it hassle-free for you, we won’t cost you for it. We are obliged to have you included in our readers list.

Read More: Emboss vs Deboss

FAQ’s; Selecting the Right Box Size for Your Products

When selecting the ideal box dimensions for your packaging needs, several key factors should be considered.

Q: How do I measure my product?

A: Start by measuring the dimensions of your product to ensure the box size you choose will accommodate it properly.

Q: How many boxes do I need?

A: Once you have your product’s measurements, estimate how many boxes will be required. The quantity may vary depending on the type of project you’re handling.

Q: What is the weight of my product?

A: It’s important to consider your product’s weight, as not all boxes are designed to hold heavy items. Always check the box’s weight capacity before purchasing.

Q: What is the purpose of the box?

A: Determine whether the box will be used for shipping or storage. If it’s for shipping, choose a box specifically designed for that purpose. If for storage, ensure the box is sturdy enough to hold the product without collapsing.

Q: What is my budget?

A: Your budget plays a significant role in choosing the right packaging solution. While focusing on quality and aesthetics, it’s important to also find a packaging supplier like us offering competitive prices without sacrificing the quality of the box.

Also Read: UPS Flat Rate Boxes